BF Engineering, une solution intelligente pour les services d’ingénierie et industriels.

NOUS SOMMES SUR LA CARTE

- Résidence Al Azhar Imm B2 ANBAR -Casablanca - Maroc

TÉLÉPHONE

TÉLÉPHONE

ADRESSE EMAIL

00.212.6.61.13.53.91

BF Engineering, une solution intelligente pour les services d’ingénierie et industriels.

NOUS SOMMES SUR LA CARTE

00.212.6.61.13.53.91

BF Engineering & Consulting supports its clients at every stage of their industrial projects with in-depth technical expertise and a methodical approach. Our services cover key areas, ranging from engineering and project management to qualification and installation audits.

We ensure the design, planning, and monitoring of industrial projects, guaranteeing execution in compliance with regulatory requirements and industry best practices.

Conceptual Design : Defining requirements and establishing initial technical orientations.

Capacity Study : Analyzing production capacities and sizing equipment.

Preliminary Design (APS) & Detailed Design (APD) In-depth studies to validate technical and budget feasibility.

Preparation of Technical Specifications : Drafting technical documents for supplier consultations.

Selection of Contractors : Assistance in choosing service providers.

Supervision & Coordination : Planning and monitoring the execution of works.

Budget Management : Cost control and investment optimization.

Acceptance & Qualification : Validation of equipment and installation compliance.

Participation in FAT & SAT Inspections: :

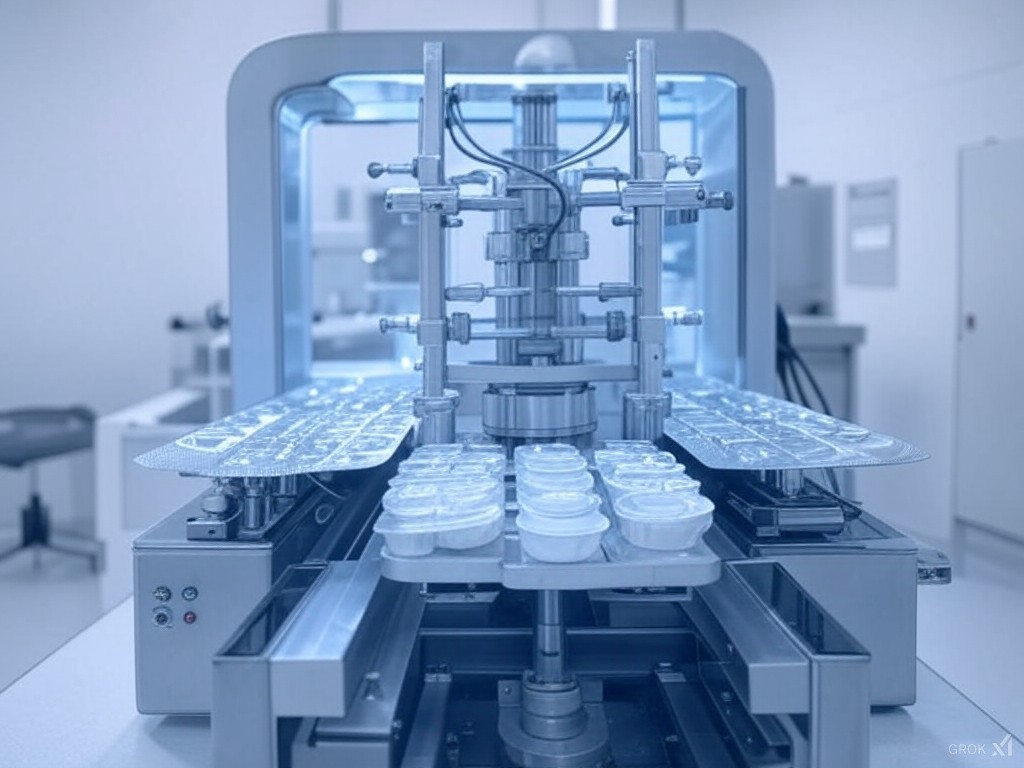

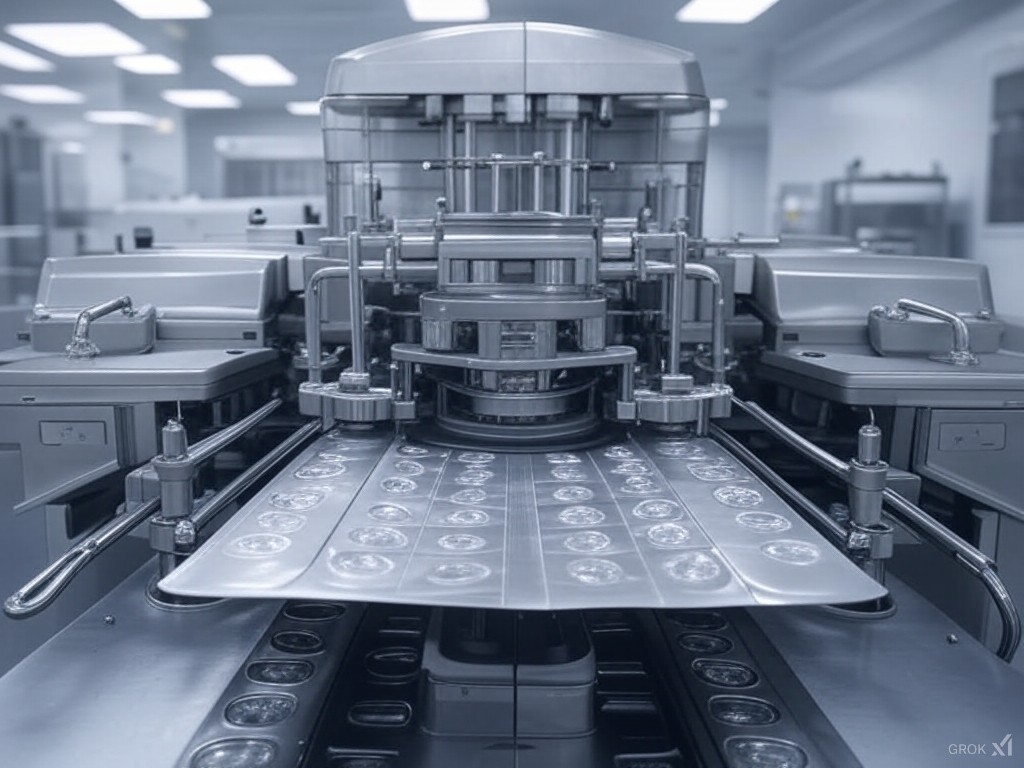

We specialize in the sizing and design of pharmaceutical production lines tailored to various dosage forms:

Complete Workshop Design & Implementation

We conduct comprehensive diagnostics of installations to ensure compliance with current standards.

We draft and execute qualification protocols to ensure regulatory compliance of equipment and installations:

We assist our clients in the reception of new equipment: